Internal Grinding Services- How and Why

Internal Diameter (ID) grinding is a precision machining process that removes material from the interior surface of a cylindrical workpiece. Using specialized grinding wheels, this technique achieves exact dimensions, tight tolerances, and superior surface finishes, making it essential for high-performance components. ID grinding can be done for components with a straight bore or with a tapered bore.

Taking Control of Our Tooling

The impact of implementing a tooling system from an efficiency standpoint are tough to quantify but are evident in our daily operations. However, we have been able to easily identify costs savings when reviewing our annual tooling spend. Over the last four years, our tooling spend as a percentage of sales has decreased each year. In a time when tooling companies are increasing prices on an annual basis, this reduction is amazing and is a testement to our tooling system.

Centerless Grinding: A Complete Guide

Explore centerless grinding for cylindrical parts: when it’s used, comparisons to similar techniques, and the process of manufacturing precise parts using this grinding method.

Swiss Precision Turning: A Comprehensive Guide

CNC Swiss Precision Turning is a specialized method of precision machining much like traditional CNC Turning. The key differentiator lies in the operational dynamics: CNC Turning involves the cutting tool moving towards the workpiece, whereas Swiss Machining maintains stationary tooling while advancing the workpiece forward using a sliding headstock mechanism. Integral to this process is the utilization of a guide bushing that serves as a stabilizing element, akin to a “steady rest,” positioned in close proximity to the cutting tool. Through this meticulous approach, any potential part deflection is minimized, thus bolstering the overall precision and accuracy of the machining process.

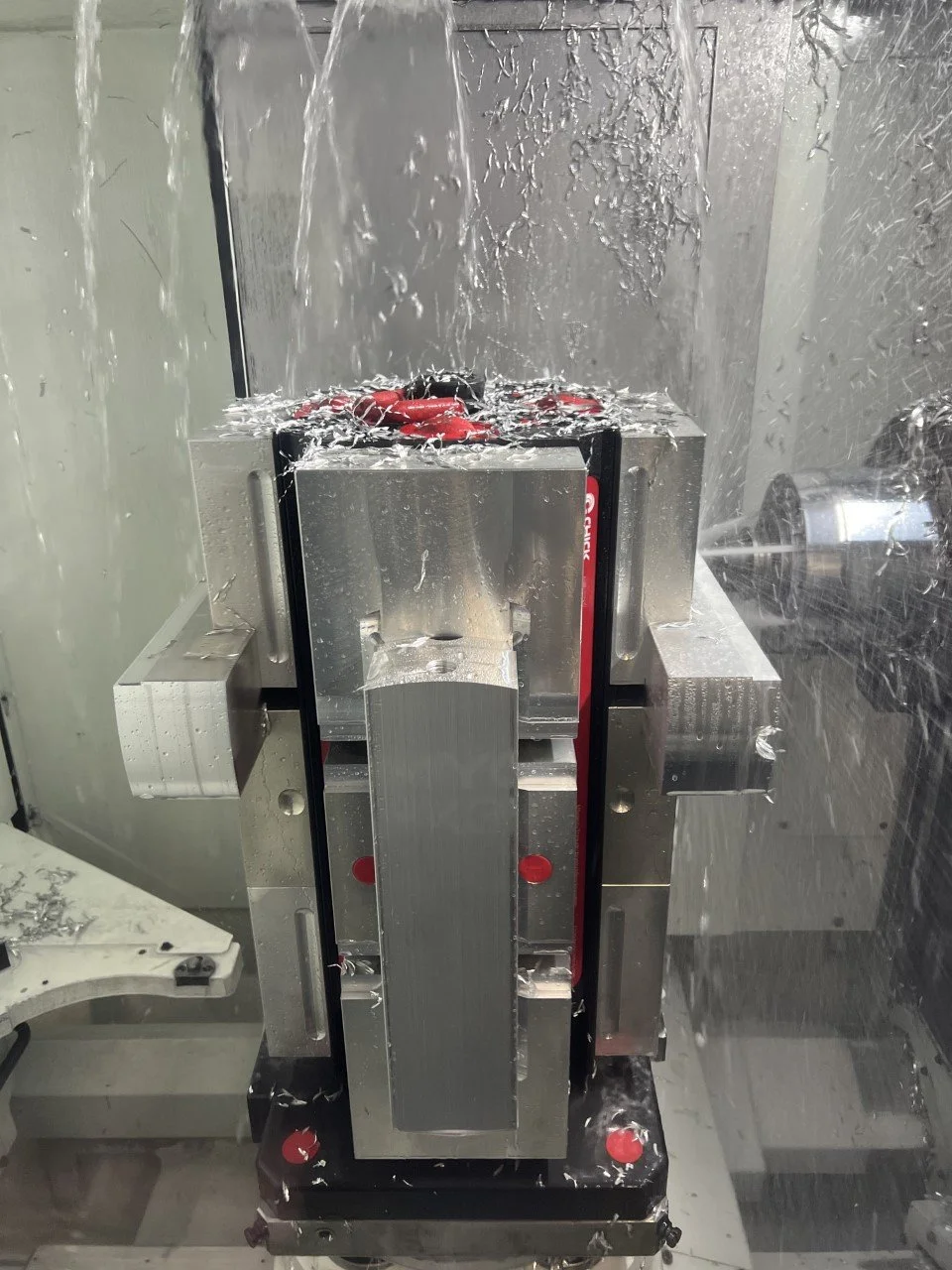

CNC Horizontal Milling for Valve Components

CNC horizontal milling for valve components can reduce cycle time and provide cost savings. Read more about the process here.

What Are the 4 Types of CNC Grinding? | Ripley Machine

Learn about the 4 types of CNC grinding: internal grinding, thrufeed centerless grinding, centerless bar stock grinding, and infeed centerless grinding.

A 5S Lean Manufacturer Expanding Capacity- Part 2

Ripley Machine is a production CNC machine shop and 5S lean manufacturer dedicated to precision, quality, and on-time delivery.

CNC Swiss Machining for Fasteners and Threaded Components

Ripley Machine offers precision CNC Swiss machining for fasteners and threaded components. We are ISO 9001 certified & near PA, OH & NY

Utilizing CNC Machining for Casting and Forgings in the Valve Industry

CNC machining of castings and forgings for the valve industry is utilization of CNC Lathes and CNC Mills (and other support equipment) to remove material to meet the tight tolerance requirements of the valve industry and IS0 9001 certified standards.

RIPLEY MACHINE: A VALUES-DRIVEN VALUE MANUFACTURER

Ripley Machine’s talented team members each bring an average of 15 years of experience to their workplace, where, since 1994, satisfied customers have received superior CNC turning, milling, grinding, Swiss turning, and casting and forging machining.

My Vacation to South Africa (Part 2- The Amazing Details of the Trip)

God blessed me with the opportunity to visit a friend in South Africa and enjoy my first vacation as an adult. What a great experience it was!

Preparing Our Business For My 2-Week Vacation to South Africa

I often heard webinars and podcasts from that stressed the differences between a healthy business and an unhealthy business. A common theme of a lot of these conversations was how many businesses operated with an owner that was completely running the business. When they looked to retire and sell the business, the business had little value. Basically, that owner had just “bought themselves a job”. I realized that was the case here at Ripley Machine

Expanding Capacity at Ripley Machine

Over the course of three decades, Ripley Machine has been striving to increase efficiency and reduce waste as well as turnover time. Check out this article explaining how!

Aluminum CNC Turning Parts Manufacturer | CNC Machine Shop

Ripley Machine is a CNC machine shop that manufactures parts & components using aluminum CNC turning. Learn more about our aluminum CNC turning.

5 Benefits to In-House Grinding

This machine shop’s in-house grinding capabilities offer many advantages for itself and for its customers, including time and cost savings.

Emerging Leader Success: Interview with Andy Reinwald

So it’s our job, not just the trade association but

also individual companies, to show what manufacturing

is all about and how vital a role it plays.