What Are the 4 Types of CNC Grinding? | Ripley Machine

The 4 Types of CNC Grinding

Ripley Machine & Tool is a CNC machine shop in Ripley, New York. We specialize in a range of different CNC machining processes, including grinding. We have an experienced grinding team with decades of experience, and when combined with a true commitment to service, competitive pricing, and significantly shorter lead times than the competition, we are proud to offer the highest quality services available.

Within the realm of CNC grinding, Ripley Machine & Tool offers four specific types: internal grinding, thru feed centerless grinding, centerless bar stock grinding, and infeed centerless grinding. What is the difference between each of these? Which one would be the best for your specific application?

What is CNC Grinding?

CNC grinding is a machining process that uses a rotating grinding wheel to manufacture parts. The process works by removing small amounts of material from a larger piece, such as aluminum or stainless steel, with a rotating high-speed wheel being used as a cutting tool. The material is rotated around a stationary wheel along multiple axes until the part is cut into the desired shape.

Utilizing grinding as a manufacturing method has many advantages. It allows for the mass production of parts, as machines are able to run for long periods of time uninterrupted. Running uninterrupted also does not affect quality, as grinding machines are able to produce high precision parts with accuracy even at very high production speeds. Producing parts with such high efficiency also reduces waste. Altogether, this makes grinding an efficient process for mass production of precision parts. If you choose to use grinding for your manufacturing needs, Ripley Machine & Tool offers four types that each have their own advantages:

Internal Grinding

Internal grinding is used to remove material from the inside of a piece. It is generally used to change the internal dimensions for cylindrical or conical parts, or more simply, to accurately finish holes in a part. Usually, the workpiece is fixed in a chuck, fixture or mounted to a face plate that rotates while the rotating grinding wheel removes material from the inside. Ripley Machine & Tool is able to grind both straight and tapered bores, with a bore diameter ranging from 0.750” to 9”, and a length of up to 7”.

This is a reference guide to contact percentage when grinding a taper bore. At Ripley Machine, we firmly believe in achieving 100% contact.

One of the more common internal grinding that Ripley Machine does is taper bore grinding. In this process, our customer specifies a taper (typically that taper will be 1-1/4” per foot) and the diameter at the large end of the bore at the face of the part. A gage with the matching taper and diameter is provided. That gage is then used to verify the taper by a processes called bluing. A trained technician will lightly coat the gage with a non-drying Prussian Blue fitting compound. The gage will gently be placed into the ground part. We then hammer the gage to seat it in the part. After removing the gage from the part, we place strips of clear tape in the bore of the part. We then remove the strips of tape and place them on paper for review. The closer the contact percentage is to 100%, the closer the taper of the bore is to the desired specification. Most customers allow for 80% contact or better, however at Ripley Machine, we believe in 100% every time. After the taper of the bore is verified, we then use the gage to verify the diameter of the parts. We calculate the diameter of the gage versus the required diameter of the bore. We then take the difference and calculate the “stand-off” for the gage. This allows us to ensure that the diameter of the ground bore meets the customer’s requirements.

Our internal grinding services can be used on any bore that requires a tighter tolerance than what is able to be machined. The most common uses of our internal grinding services are gear hubs, impeller hubs, couplings and bushings.

Thrufeed Centerless Grinding

Thrufeed centerless grinding works by passing the workpiece through the machine, where material is removed by a grinding wheel. It has a broad range of uses and is considered to be one of the most efficient grinding processes. Due to tight tolerances, it can provide smoother surface finishes. Thrufeed centerless grinding works best on higher quantities where the ground diameter is the largest, as the part can more easily pass through the grinding zone. We can grind parts with a diameter ranging from 0.063” to 2.5”, with tolerances as tight as 0.0003” and surface finishes better than 8 Ra.

The picture on the left shows an example of a typical thrufeed centerless grinding job. As you can see, the bushings are sent through the grinder one after another. An operator on the other side of the machine sizes the parts utilizing micrometers, air gages, or other similar measuring equipment.

When quantities are high enough, Ripley Machine will invest in various automation equipment to help maximize efficiency while ensuring the highest of quality.

We have worked with several customers who were struggling to maintain a tolerance or surface finish on an expensive CNC Lathe or CNC Swiss machine. We worked with our customer to allow them to hold a loose tolerance on their turning operation and we ground the parts after machining. While this obviously added the cost of grinding, our customers agreed that our grinding charges were minimal when compared to their savings on the machining of the part. With the struggles for skilled labor over the last few years we have found that the addition of grinding operations has actually helped to address the problems. By allowing for a looser tolerance on a CNC Lathe or CNC Swiss machine, there is less skill required for the lathe operation. Parts are then sent to Ripley Machine where our trained grinding experts, grind the parts to the tight tolerances required.

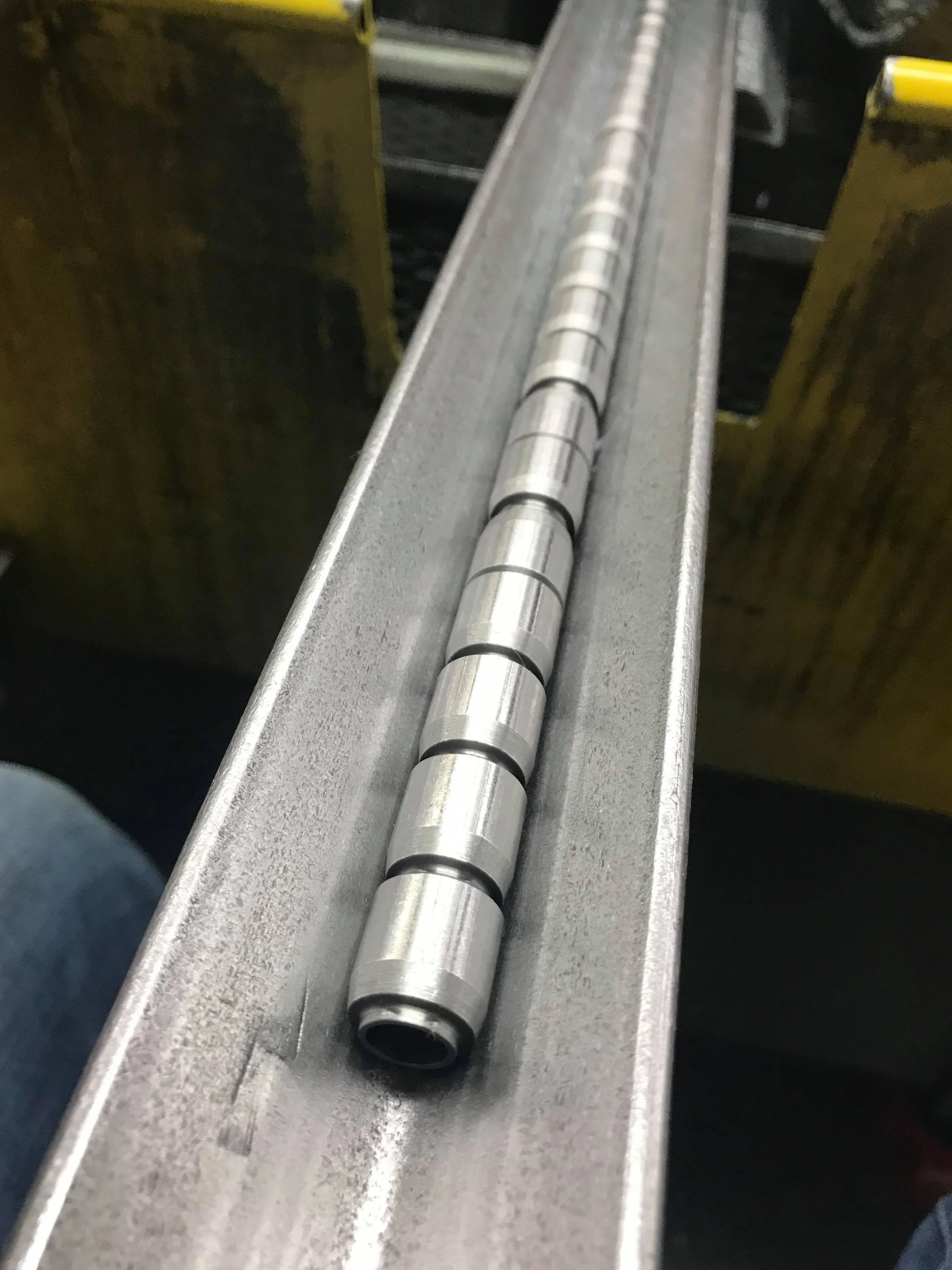

Centerless Bar Stock Grinding

Centerless bar stock grinding is similar to thrufeed grinding in that the workpiece passes through the machine. It is spun on a regulating wheel while a material is removed by a grinding wheel. Ripley Machine & Tool has the capabilities to grind bars up to 1” in diameter and 14’ in length. We are able to grind customer supplies material or provide the material ourselves from one of our qualified vendors, and have experience with grinding a wide variety of materials including tool steel, stainless steel, aluminum, Hallestoy, brass, copper, plastic, and more.

Ripley Machine has utilized our centerless bar stock grinding programs to help our customers address the supply chain issues created over the last few years. Our customers may not be able to get their desired bar stock size due to supply chain issues. We have allowed our customers to purchase a larger diameter material than required and ground that material to the customer’s desired finish diameter.

Our bar stock grinding services also come in handy for customers with CNC Swiss Machines. When the cost and lead time for a guide bushing and collets for a CNC Swiss machine exceed what is demanded for a project, we can grind material to a size that matches a currently stocked collet and/or guide bushing. We have had several customers who were faced with the spending several hundred dollars and waiting several weeks in order to get a collet and/or guide bushing that would fit their purchased material. We were able to grind the bar stock to a size that fit the collets and guide bushing that our customer already had. We were able to complete the grinding in a couple of days and cheaper than purchasing new guide bushings and collets. In addition to saving cost and time, our customer was also working with ground material which allowed for them to hold tighter tolerances on their Swiss machine.

Infeed Centerless Grinding

These needle valve stems demonstrate ideal infeed centerless grinding.

Infeed centerless grinding, also known as end-feed or plunge-feed grinding, is a process where the part does not pass through the machine. It involves holding the workpiece in place while the grinding wheel is fed into it, and is generally used for more complex parts that have unique dimensions and tight tolerances.

If the part you need has a shape that doesn’t allow it to pass through the grinding area, infeed centerless grinding can be used to grind the diameter to the right size. A part may be unable to pass through the grinding area because the ground portion of the part isn’t the biggest diameter on the part. One of our most common uses of infeed centerless grinding is with needle valve stems where we are grinding up to the shoulder of the part.

Another application for an infeed centerless grinder is when a profile with multiple diameters needs to be ground. We can modify our grinder to dress these forms onto the wheels and blade.

Our infeed grinder can grind parts up to 4” in diameter and up to 6” long, with tolerances of 0.0003” and surface finishes better than 8 Ra.

Ripley Machine’s CNC Grinding Services

Ripley Machine is known for assembling a grinding team with an exceptional average experience of 25 years. This extensive experience is coupled with a strong dedication to continuous improvement, ensuring that the team constantly seeks better ways to meet and exceed customer expectations.

The year 2023 was particularly noteworthy for us, as our team received both the NTMA Safety Award and the NTMA 6S Excellence award. These accolades serve as a testament to our unwavering commitment to maintaining a safe and pristine work environment.

As an ISO 9001:2015 Certified machine shop specializing in centerless and internal grinding, Ripley Machine & Tool brings decades of expertise, a steadfast dedication to service, efficient lead times, and competitive pricing to the table. Our pride lies in offering the finest services in the region. We invite you to reach out to us today to discover more about the comprehensive range of services we provide.