A 5S Lean Manufacturer Expanding Capacity- Part 2

Ripley Machine is a production CNC machine shop offering CNC Turning, CNC Milling and CNC Grinding in the Buffalo, NY area as well as across the United States. This is the story of our journey to become a 5S Lean manufacturer. The business was founded in the 1950s and was incorporated by Quentin Bensink in 1994. The business has stayed in the family for decades, with Bensink’s grandson Andrew taking over in 2015. Beginning in 2017, the company began a pattern of annual growth of 10% or more through the present time. In the wake of this growth and some of the labor and supply shortages that presented during the 2020 COVID Pandemic, the Ripley Machine management team recognized the need for expanded capacity with minimal capital investment and minimal increases in expenses.

We began to take numerous steps to increase our capacity, you can learn more about our journey here: Expanding Capacity at Ripley Machine. The underlying concept from all the steps we have taken to increase capacity has been lean manufacturing.

Several years ago, members of our team read 2 Second Lean by Paul Akers and realized that our own shop related to Paul’s 5S lean journey. For those that haven’t read the book, Paul begins by talking about how much pride he took in his shop. He even had been recently given a stamp of approval by his banker “Paul, I would loan you any amount of money you want. I have never been to a business so well run and organized.” Paul soon had a consultant introduce him to lean concepts, and the pride from the banker’s remarks quickly turned to embarrassment. The book continues to give a basic and simplistic introduction to lean initiatives and how they transformed Paul’s company. This transformation resonated with members of the Ripley Machine team, and we knew we had to set out on a 5S lean manufacturing journey of our own!

Our team decided to incorporate a dedication to continuous improvements into our quality management system. One of our quality objectives that was reviewed monthly was “improvements made”. Any time a team member made an improvement (no matter how small), we recorded it and counted it towards our monthly objectives. The goal of these improvements was to eliminate waste, but we didn’t limit it to just that. In a typical week, each one of our team members makes some form of recordable improvement. Since 2020, our team has made over 2500 improvements!

Then, our team began to perform 5S activities with a specific focus on the first 3, where we would Sort, Set-In-Order and Shine work areas. Over the last 3 years, our team has removed over 6 dumpster loads of “clutter” from our shop. Each day every member of our team spends time focusing on 5S in their work area.

As we began to remove clutter and started to focus on the set-in-order of 5S Lean Manufacturing, we realized that our tooling storage was a mess. We had tools all over the place and often had duplicates of tools that were completely unnecessary. Much of the “clutter” that we discovered when we did our sorting was our tooling management area. We decided to embrace the tooling management system inside of our ERP (ProShop ERP) to gather and enter every tool inside of our shop. We then moved all tooling to a single spot in the shop. Each tool has its own page in our ERP that lists the tool’s attributes, re-order points and other important information. We can easily search the system by attribute to help us find a tool that we can use for a particular job.

The tooling project has paid dividends in the last two years with a drastic reduction in costs. Despite double-digit sales growth and significant vendor price increases over the last two years, we have cut our spending on tooling and shipping in half during this time. These savings have allowed us to help offset other price increases while ensuring that we are paying our team members as much as possible and keeping our customer prices as low as possible.

With our team fully embracing the sort, shine and set-in-order steps of the 5S Lean journey, we started to focus on standardizing and sustaining.

One of the most daunting tasks of our 5S Lean Journey was to standardize. Our first step to accomplish this was utilizing our ERP software to establish “checks” to ensure that we had a scheduled time frame and interval for accomplishing tasks. This included machine maintenance. Unfortunately, the only maintenance that was previously done at Ripley Machine was necessary maintenance. However, we recognized the need to accomplish preventative maintenance. Each piece of equipment in our facility has its own page in our ERP where we can set up regularly scheduled tasks of preventative maintenance. We also automated scheduling of various cleaning tasks to help ensure they were accomplished.

The final pillar of 5S Lean Manufacturing is “sustain”. Thankfully, our management team is completely dedicated to a 5S Lean transformation and is working relentlessly to ensure that we are “sustaining”. Every member of our team is required to spend time each day working on 5S Lean. We recognize achievements towards 5S Lean through our daily and monthly company updates. We also dedicate one week a month to Lean Manufacturing. During this week, all of our daily updates revolve around lean. We educate our team on 5S Lean and how it applies at Ripley Machine.

This is just a glimpse into the transformation that our team has undergone over the last several years. This dedication to continuous improvement and lean has helped us to expand capacity and better serve our customers. The joy of this focus is that we will never stop improving. We continue to work with our team to figure out how we can improve on a process that is working “good enough” and make it work great!

If you are looking for a growing machine shop and 5S lean manufacturer that is dedicated to continuous improvement with a focus on serving our customers, be sure to request a quote today.

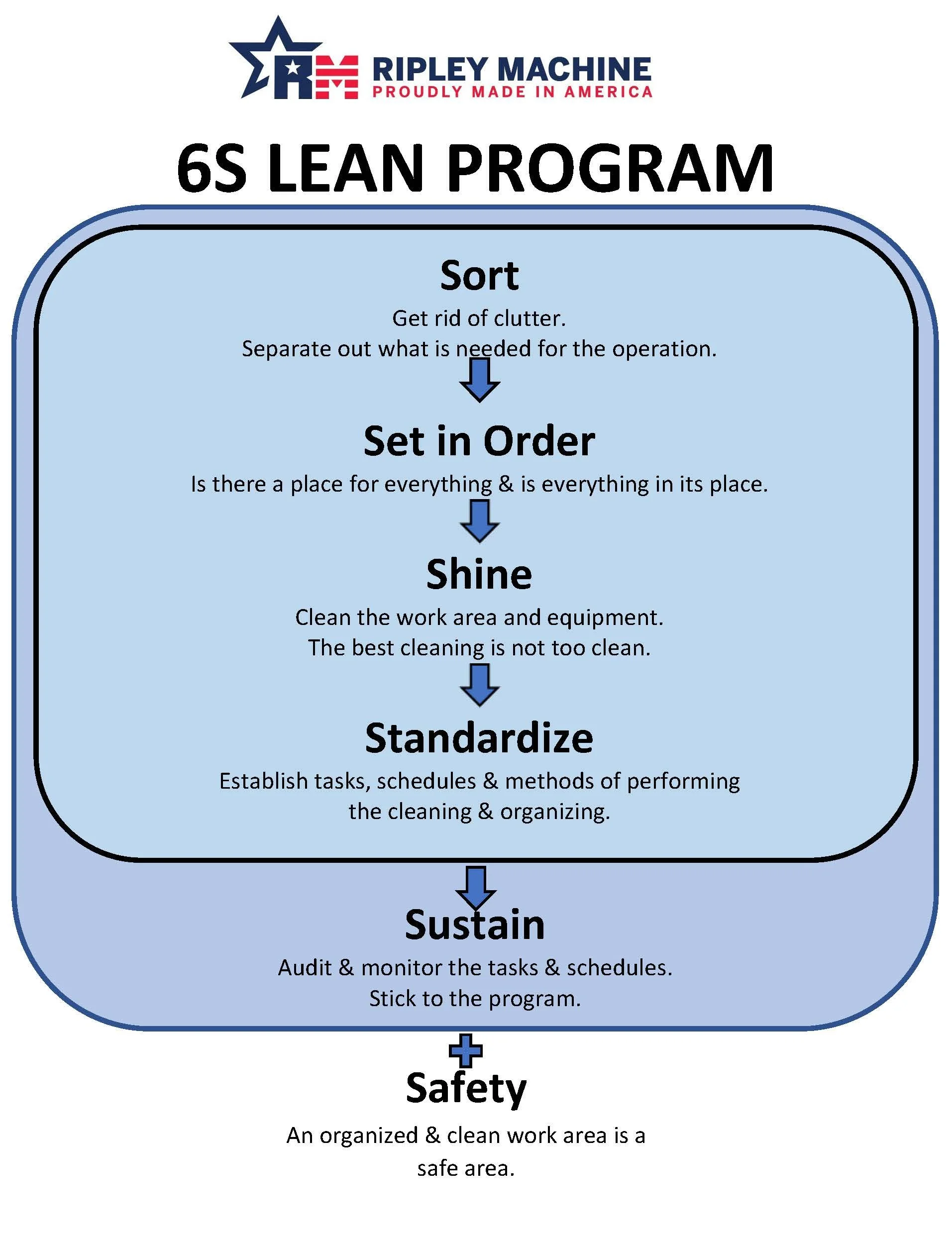

*Author’s note: Ripley Machine puts the highest regard for safety. To ensure a focus on safety, we have adopted the “6S Lean” focus where we add “safety” as the sixth pillar of lean. For this blog, we used the more commonly known “5S”.

We promote 6S Lean to our team on a daily basis and encourage and require every team member to be an active participant.

We removed carts of old honing parts and equipment during 5S Lean initiative.

We removed over 10 trailer loads of junk from our facility as part of our 5S Lean initiative.