A High-Volume Machine Shop You Can Depend on

How do we define a high-volume machine shop?

Here at Ripley Machine, our diverse range of manufacturing capabilities creates a somewhat flexible definition when it comes to quantities classified as high-volume. When considering our Swiss CNC Turning department, high-volume production can range from 5,000 to 20,000 pieces. In our CNC Turning department, we typically define high-volume as falling within the range of 1,000 pieces to 10,000 pieces. For parts that exceed 5 inches in diameter, we consider high-volume to be anything above 100 pieces. As an ISO Certified machine shop, our dedicated team is highly experienced in meeting your specific demands on high-volume orders, ensuring that we maintain high standards in terms of price, timely delivery, and overall quality.

What machines are used in high-volume machined work?

Our most common machines utilized to efficiently produce high-volume machined components are our advanced CNC Swiss machines. These CNC Swiss machines are meticulously designed with high-volume production in mind, ensuring precision and reliability in every task. Learn more about the capabilities of CNC Swiss Turning Machines and discover how they can effectively serve you and enhance the efficiency of your project here.

High-Volume Swiss Machined Stainless Steel Valve Components

We also utilize CNC Lathes in meeting high-volume demands. Our CNC Turning centers are equiped with bar feeders, live tooling, high pressure coolant,etc. to help produce parts in the most efficient manner possible.

Our CNC Milling department uses a variety of tools to efficiently produce high-volume machined components. For components machined on our standard CNC Vertical Machining Centers, we utilize fixtures that allow us to produce multiple parts at once. Our Horizontal Machining Center is equipped with pallet changing system and tombstone fixturing to help in increase efficiency for high-volume

Our grinding department utilizes CNC as well as other automation tools to help meet the demands of high-volume machining.

What industries does Ripley Machine serve with high-volume machining?

Ripley Machine can serve a variety of industries when it comes to high-volume. Companies in oil and gas, the valve industry, Heavy Trucks, Industrial, Medical, Firearms and Defense have all utilized high-volume services from Ripley Machine.

How does Ripley Machine meet the quality demands of high-volume machining in ways that other machine shops do not?

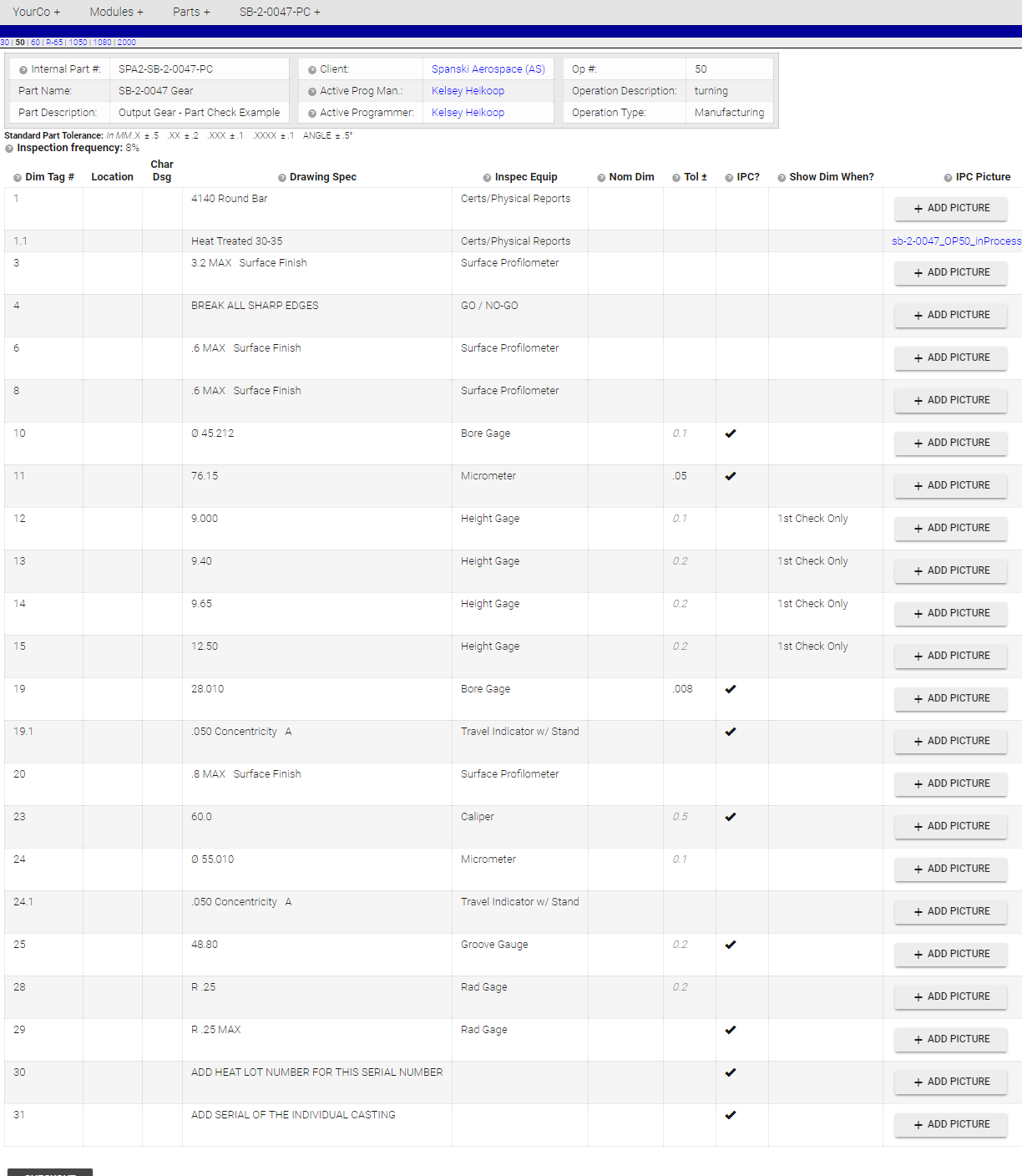

Our team reviews each part for all inspection requirements and utilizes our ERP to ensure that inspection requirements are met.

Ripley Machine is an ISO Certified machine shop. Many shops see ISO certification as a necessary evil to meet customer requirements. However, at Ripley Machine, we embrace it! Our team embraces quality and our quality management system.

When we start a new project, our team reviews the project extensively as part of the contract review. Our goal is to find any possibility for error on the job. If there are questions on the prints or specifications for a job, we immediately reach out to our customers to help ensure that everyone is on the same page.

After we accept the order, our team adds part checks inside of our ERP. Our ERP (ProShop ERP) allows for us to setup part checks with detailed instructions for how to check each dimension of a part. We are also able to add pictures or other files to help ensure that operators are aware of proper inspection. We are also able to establish In Process Check requirements. We can establish these checks for a every part or at certain frequencies. This can vary per dimension. In some cases, our team will record tight tolerance dimensions on every part and then record other dimensions every 10th part.

Our management team is actively reviewing these requirements and production to ensure that we are preventing any escapes of non-conforming product while also ensuring that we operating efficiently.

Our team is able to provide inspection results and in process measurments as part of shipping paperwork to give our customers the peace of mind that their high-volume machined component meets their quality requirements.

Prototype to Production

The Ripley Machine team is proud to have collaborated on countless projects where we worked with the engineering team to manufacture prototypes. Our team is willing to help customers in understanding the manufacturing process to help ensure that new parts are designed with manufacturability in mind. We have often helped customers identify design flaws such as improper material, failure to account for plating allowance or parts where the tolerances were too loose or too tight for what the customer needed. At Ripley Machine, we like to get to know our customers and what the products are being used for. We firmly believe that it is part of our job to not only provide parts that meet customer print requirements but also parts that will function as the customer desire.

As your project transitions from prototype to production, we are here to serve you. Our team is very familiar with the prototype to production process. Our team is able to adapt and efficiently manufacture a small quantity of parts for you to test your new design. We are then able to machine “medium quantities” as your project begins to gain some steam. When your project takes off, our team is still ready to serve you.

Our ERP plays a huge role in this process as well. Every job that we process, our team makes extensive notes inside of our ERP to ensure that we are able to produce parts the next time that you are ready to order. Our team links all tooling and records tool life. This allows us to easily to determine tooling required on future orders when we receive an order. We also are able to make notes about how a job ran and any opportunities for improvement in the future. This allows us to attack each repeat order in an efficient manner. The data that we have in our ERP allows us to provide you with the lowest price and a short lead time when it comes time for a production order. We are well aware of how long it can take for a project to go from prototype to production. Our team and our ERP help ensure that there is nothing to forget in the lapse of time from prototype to production.

When we work with customers in the intial prototype stages of a project, we are sure to break out costs that would be one-time costs such as non-recurring engineering. Our customers have always noted how appreciative of this.

Ripley Machine is ready to serve your high-volume machining needs.

Our team is dedicated to customer service. Everything we do is done with the thought of best serving our customers. Whether you are looking to replace a vendor in an already established high-volume machining project, or you are in the early stages of a project, our team is here to serve you. We encourage you to contact us today for help meeting your requirements.