Centerless Grinding: A Complete Guide

Centerless Grinding – How it Works, When It’s Used, and Everything In Between

Definition of centerless grinding

Centerless grinding is a machining process where cylindrical parts are ground to precise dimensions and surface finish without the need for centers or chucks. It involves feeding the workpiece between two grinding wheels, one regulating wheel and one grinding wheel, which rotate in opposite directions, removing material until the desired size and finish are achieved.

Centerless grinding is commonly used for producing cylindrical components with tight tolerances and smooth surface finishes, particularly in industries such as automotive, aerospace, and medical device manufacturing. Unlike traditional grinding techniques that require centers or chucks to hold the workpiece, centerless grinding allows for high-volume production of parts with minimal setup time and increased efficiency.

History of Centerless Grinding

The history of centerless grinding traces back to the early 20th century, with significant developments occurring in the 1910s and 1920s. One pivotal moment was the invention of the centerless grinder by Cincinnati Milacron in 1920, revolutionizing the precision machining industry. This breakthrough eliminated the need for centers or chucks to hold the workpiece, allowing for continuous grinding of cylindrical components. Moreover, the introduction of hydraulic systems in the 1930s further enhanced the efficiency and accuracy of centerless grinding machines. This information draws from "Machine Tool Practices" by Richard R. Kibbe, Roland O. Meyer, Warren T. White, and Kelly Curran, a widely recognized textbook in manufacturing engineering that provides comprehensive coverage of machining processes and their historical development.

How Centerless Grinding Works

Workpiece Setup:

The process begins with the preparation of the workpiece, which is typically a cylindrical metal component. The workpiece is placed between the grinding wheel and the regulating wheel, with the latter applying pressure to control the rotation and feed rate of the workpiece.

Feeding the Workpiece:

The workpiece is fed into the grinding machine between the grinding wheel and regulating wheel. The grinding wheel, rotating at high speed, removes material from the outer diameter of the workpiece, while the regulating wheel controls its rotational speed and axial movement.

Grinding Operation:

As the workpiece advances through the grinding zone, the grinding wheel removes material from its outer surface, shaping it to the desired diameter and surface finish. The regulating wheel maintains a consistent rotational speed and applies pressure to ensure precise grinding.

Continuous Rotation:

Unlike traditional grinding methods that require stopping and repositioning of the workpiece, centerless grinding allows for continuous rotation of the workpiece, resulting in higher productivity and efficiency.

Size Control:

To achieve the desired size and tolerance, adjustments are made to the position of the regulating wheel relative to the grinding wheel. These adjustments control the depth of cut and ensure uniform material removal across the entire length of the workpiece. Depending on numerous factors, centerless grinding can produce parts with tolerances of less than .0001”.

Surface Finish:

The combination of the grinding wheel's abrasive action and the regulating wheel's control produces a smooth surface finish on the workpiece. This is essential for applications requiring high precision and quality surface finishes. This helps to produce surface finishes of better than 10RMS.

Final Inspection:

Once the grinding process is complete, the workpiece undergoes a final inspection to ensure it meets the specified dimensional tolerances and surface finish requirements. Final Inspection processes are established on a job-by job basis to help ensure that each part ground meets customer requirements.

Repeating the Process:

Centerless grinding is often performed in a continuous cycle, with workpieces fed into the machine one after another. This allows for high-volume production of cylindrical components with consistent quality and precision.

By following this step-by-step process, centerless grinding achieves tight tolerances, excellent surface finishes, and high productivity, making it a preferred machining method in various industries.

Types of Centerless Grinding

Thru-feed, in-feed, and end-feed centerless grinding are three primary methods used in centerless grinding, each with its distinct advantages and applications:

Thru-feed Centerless Grinding:

Process: In thru-feed grinding, the workpiece is fed continuously between the grinding and regulating wheels. The grinding wheel removes material from the entire length of the workpiece's outer diameter as it passes through the grinding zone.

Advantages: Thru-feed grinding is well-suited for high-volume production of cylindrical components with consistent dimensions and surface finishes. It offers efficient material removal rates and requires minimal operator intervention, making it ideal for mass production applications.

Applications: Thru-feed grinding is commonly used for producing long, straight parts such as shafts, pins, and rods in industries like automotive, aerospace, and manufacturing. Thru-feed grinding is often used at Ripley Machine to grind raw bar stock in preparation for machining operations.

In-feed Centerless Grinding:

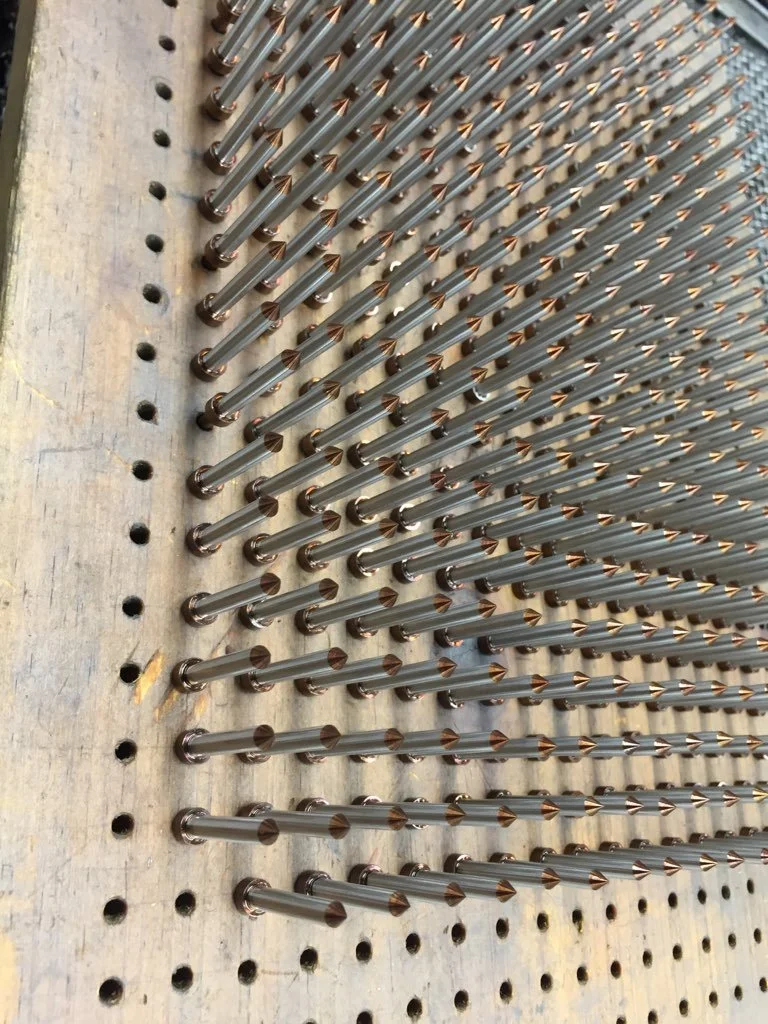

We utilize in-feed centerless grinding to grind these high pressure needle valve stems.

Process: In in-feed grinding, the workpiece is fed axially into the grinding machine between the grinding and regulating wheels. Material removal occurs by incrementally advancing the workpiece into the grinding wheel until the desired size and shape are achieved.

Advantages: In-feed grinding allows for precise control over the depth of cut, making it suitable for grinding complex shapes, shoulders, and tapers. It offers flexibility in machining various workpiece geometries and is well-suited for small batch production or applications requiring tight tolerances.

Applications: In-feed grinding is commonly used for producing short, cylindrical parts with intricate features or multiple diameters, such as gears, bushings, and spools, in industries like aerospace, medical, and precision engineering.

End-feed Centerless Grinding:

Process: In end-feed grinding, the workpiece is fed axially into the grinding machine, but only the end of the workpiece makes contact with the grinding wheel. Material removal occurs by grinding the end face of the workpiece until the desired length is achieved.

Advantages: End-feed grinding is suitable for machining workpieces with a significant length-to-diameter ratio or for producing parts with specific end requirements, such as chamfers or tapers. It offers precise control over the end dimensions and is often used for finishing operations.

Applications: End-feed grinding is commonly used for producing parts like needles, pins, and plungers, as well as for finishing operations on components produced by other machining processes.

In summary, each method of centerless grinding offers unique advantages and is selected based on factors such as the type of workpiece, production volume, dimensional requirements, and surface finish specifications. Thru-feed grinding excels in high-volume production, in-feed grinding offers versatility for complex shapes, and end-feed grinding is ideal for finishing operations and parts with specific end requirements.

Applications of Centerless Grinding

Centerless Grinding can be used on a variety of applications across all industries. Here are some common applications where Ripley Machine serves its customers with centerless grinding services:

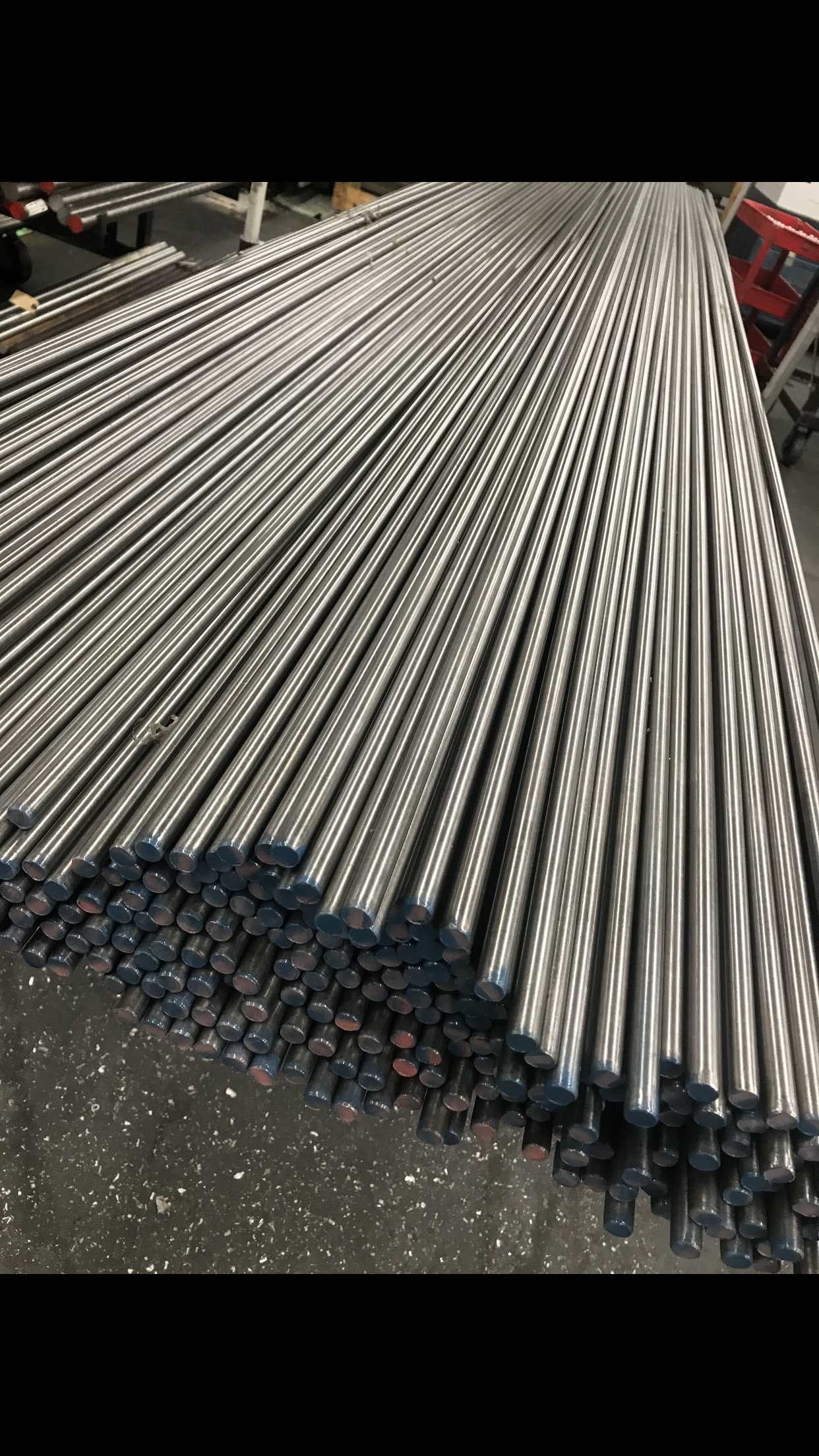

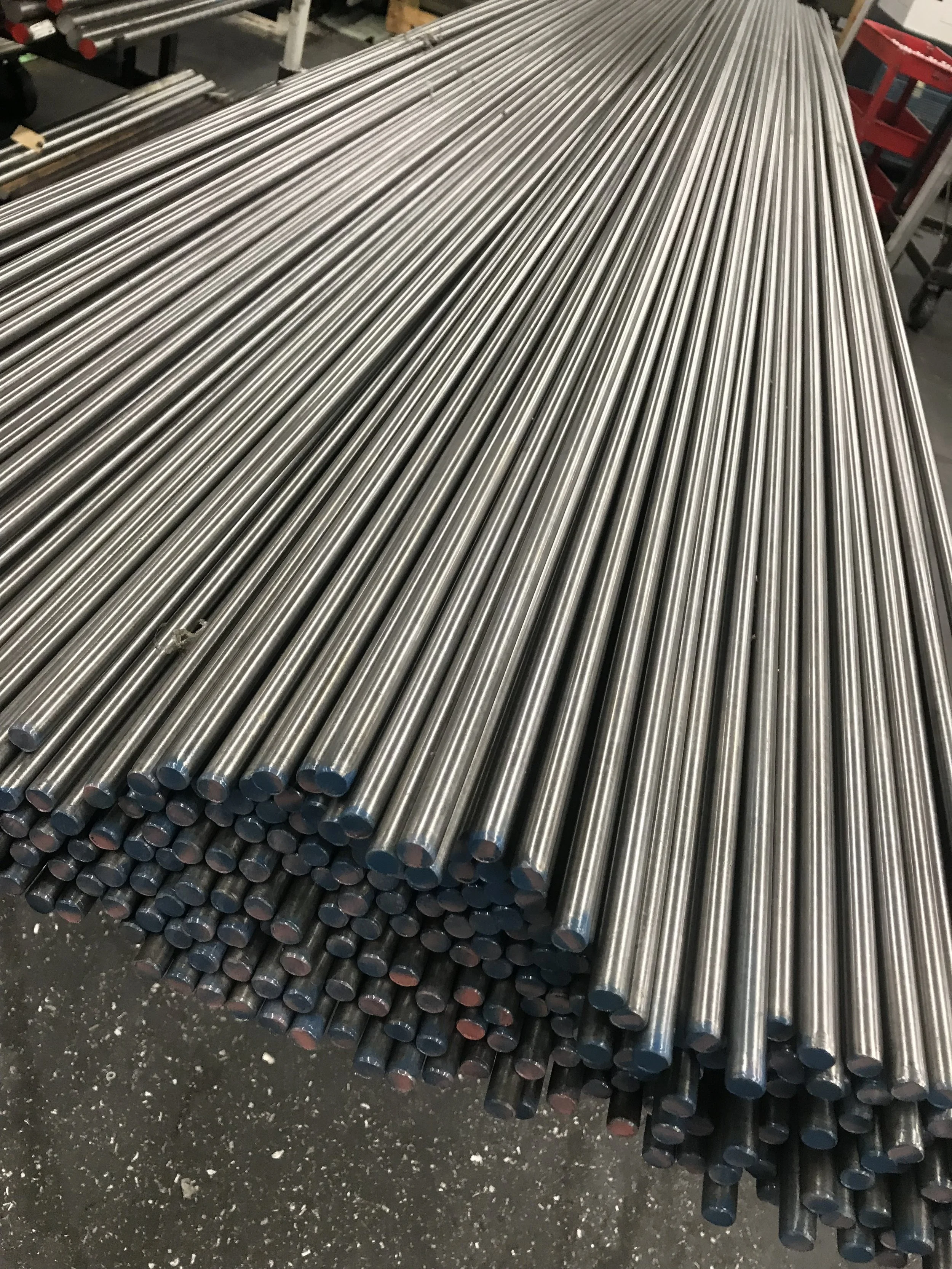

Centerless Ground Steel Bar Stock

Our customer purchased this material and had it drop shipped to our facility. We the ground it and delivered it to their facility. Bars were bundled to allow for easier handling.

We grind raw bar stock for other machine shops (specifically those with Swiss and/or Screw Machines). Ground bar stock can serve several purposes:

Centerless ground bar stock can be used in Swiss Machine applications to help ensure that material is held to a tight tolerance which will help eliminate issues with collets and guide bushings as well as help with holding tighter tolerances and finishes. (Visit our blog on Swiss Machining to learn more about how ground bar stock impacts Swiss Machining.)

Reduce cycle time by grinding bar stock to finish diameters. In applications where efficiency and cycle time is of the utmost importance, it can make more financial sense to have Ripley Machine provide centerless ground material to size instead of having to turn the outside diameter of a part, saving precious machine time. We also will grind difficult to machine materials to help eliminate the need for turning.

Centerless ground bar stock can be ground to any diameter. This means that we can grind bar stock to fit into a collet or guide bushing that our customer already has. This helps to save tooling costs and also helps to reduce lead time (no need to wait on a purchased guide bushing). We can also grind bar stock to the major diameter of a thread. This helps to prevent the part falling out of your guide bushing and allow for a continuous thread.

Our team can centerless grind needle valve stems that require an in-feed grinding application to ensure a tight tolerance and smooth surface finish. Our in-feed centerless grinder allows our team to get close to a shoulder or an undercut.

We frequently centerless grind bushings, pins, stems, pistons, valve components and other components after heat treating for internally manufactured components as well as for other manufacturers. This helps our customers to meet tight tolerances on heat treated parts that would not be possible without grinding due movement in the heat treat process.

Our centerless grinding department will often work as an outsource option for customers who have centerless grinding but can’t meet requirements due to various constraints. We have ground for customers to solve a capacity issue. We have also centerless ground parts in a prototype or production manner for customers who weren’t setup for the respective quantities.

Centerless grinding can be used to eliminate a small mismatch, rough surface finish, minimal chatter, workholding marks or other defects in surface finish left behind from a CNC Turning operation. This allows CNC Lathes to spend more time running parts and less time chasing a surface finish.

Advantages of Centerless Grinding

Centerless grinding is able to achieve tight tolerances and surface finishes that normal CNC Machining would not typically be able to achieve. Depending on the diameter, length and material of a part, we can often hold tolerances as close as .0001” and achieve surface finishes as good a 5 RMS. Tolerances of .0005” and a surface finish of 16 RMS can be achieved with virtually minimal effort in a centerless grinding application.

Centerless grinding can also be utilized to increase production. We have worked internally and with customers to review processes and determine that the addition of a centerless grinding operation can actually save time and money. While the addition of the operation obviously adds up front costs, the savings in machine and operator time far outweigh the minimal costs of centerless grinding.

Challenges of Centerless GrindingThe biggest challenge of centerless grinding is the setup process. It has often been said that “centerless grinding is an art”. The work blade that the workpiece rides on must be set at the proper height, above centerline of the two wheels. An improper setup can cause issues with chatter, out-of-roundness, straightness, among other issues. Thankfully, our team at Ripley Machine averages over 20 years of experience in working with centerless grinding setups. This enables to ensure a fast and proper setup each and every time.

Another common challenge of centerless grinding is the proper selection of grinding wheel. Different jobs require different wheels. Having the improper wheel (a bond, grain size or hardness that isn’t suitable for the material and/or application) could cause issues in the grinding process. The experienced staff at Ripley Machine is familiar with different grinding wheel options and the best use of each wheel based on the application. We also work closely with the team at Perry Mill Supply to help identify proper grinding wheels and emerging technologies to ensure that we are always using the best grinding wheel for our application.

When grinding bar stock, the straightness and out-of-roundness of the mill supplied material can often create challenges. While our grinding process can improve the out-of-roundness state of material, there are limits as to how much we can improve it. In cases where material isn’t straight or is out-of-round, we work with qualified vendors for straightening services prior to our team grinding the material.

The Future of Centerless Grinding

Blending New Technology with an Old Process

The general concept of centerless grinding has generally remained the same since its inception. While the concept remains the same, the equipment is quickly changing and evolving. Centerless grinders can now be equipped with Computer Numerical Controls (CNC). CNC Controls are commonplace for most machining processes in the 21st century. Adding CNC Controls to a grinder can serve a lot of purposes. First off, it helps to ensure precises adjustments to the machine. When coupled with proper sensors, the CNC controls can ensure that proper adjustments are made to the grinding wheel and the desired finish grind size is achieved. The addition of CNC controls can also help in the dressing of the grinding wheel. CNC controls allow for stepped or other features to be added to a part. Without CNC controls, this would only be possible by utilizing a custom cam to operate the dresser on. CNC controls can also be coupled with sensors to automatically compensate for wheel wear while the wheel is in a cut. When properly used, this helps to provide a more accurate part as well as eliminate human error.

The utilization of automation is also an emerging technology that is being adopted for centerless grinding. Centerless grinders can be equipped with robots or other loading and unloading tool, such as bowl feeders. This automates the task of putting workpieces into the centerless grinder and removing them from the grinder.

As the world continues to evolve, there are sure to be more advances in centerless grinding and the technology utilized. Internet of Things (IoT) and Artificial Intelligence (A.I.) will certainly play a role in centerless grinding in the future. Ripley Machine is constantly evaluating advances in technology and how they will impact our business, specifically our grinding departments.

Conclusion

Centerless grinding is a process that has been around and popular for over 100 years but still remains a viable process for meeting the demands of customers in 2024 and beyond. Ripley Machine’s experience along with investment in the future allows us to meet our customers demands. We encourage you to reach out to our team to learn more about centerless grinding and its impact on you and your manufacturing process.

References

https://www.sciencedirect.com/topics/engineering/centerless-grinding

https://www.sme.org/technologies/articles/2017/may/tips-trouble-free-centerless-grinding/

See Also