This is to be used as a guide to chasing parts

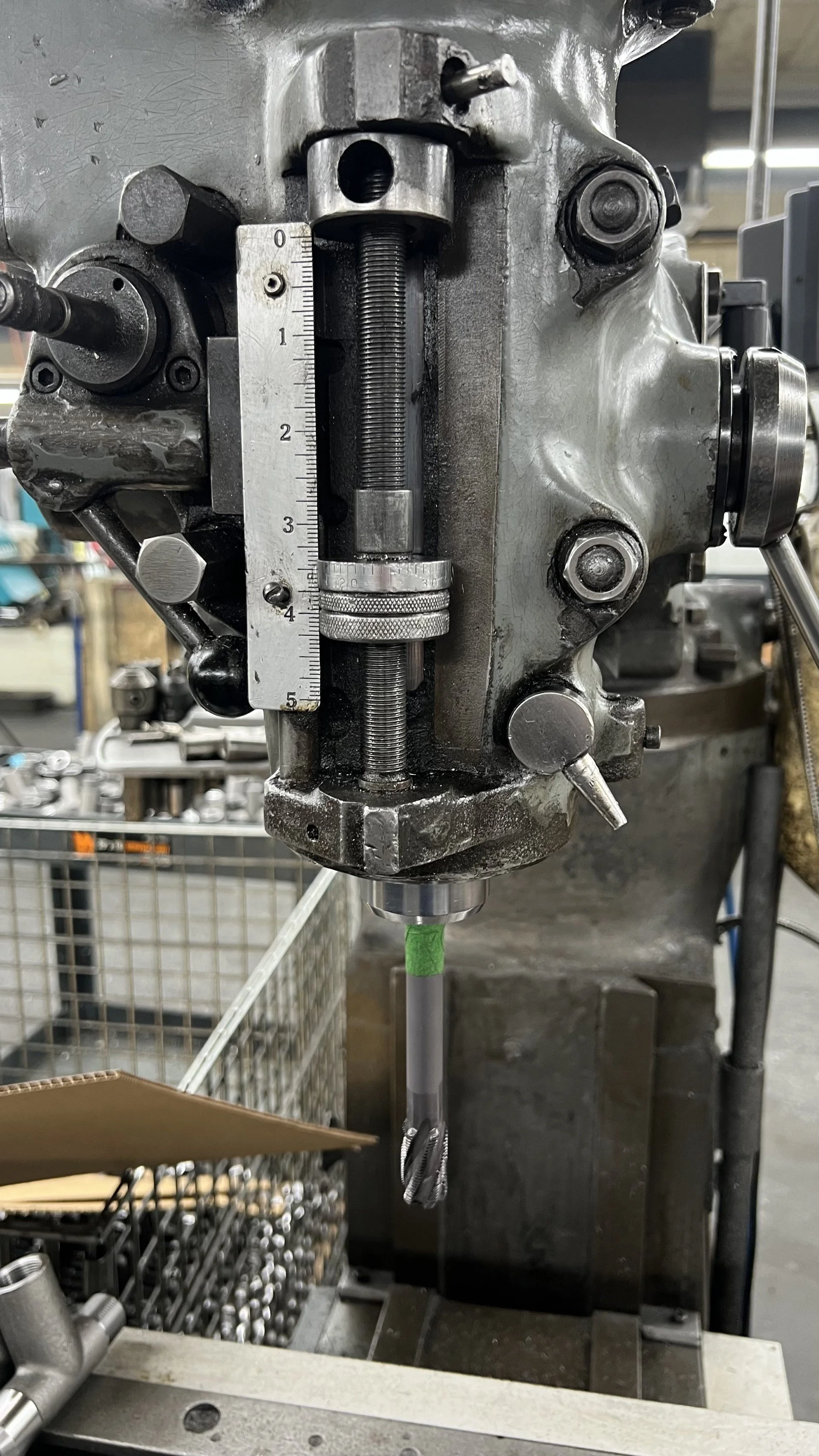

Belt should be in the top pulley in “high speed” (high range)

Use Swiss Oil (Hangsterfer’s HardCut NG22) to lightly lube tap.

Make sure that the quill is locked at the top of its travel.

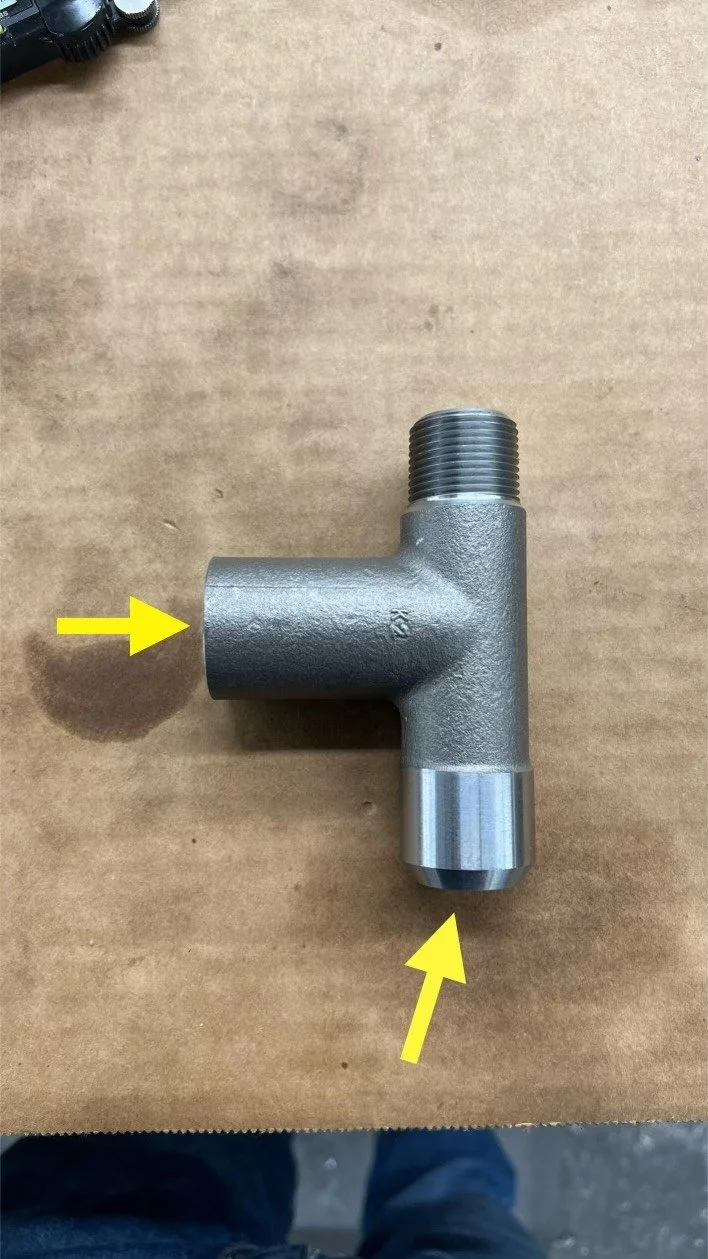

Chase part. Make Sure that tap breaks out into the counter bore of the 3/4” NPT end of the part.

We typically wrap tape on tap at location that must be reached. Make sure to stop the machine before part hits the face of the drill press.

When setting the part up, stop at the top and ensure that tape is high enough.

Inspect both holes for chips or burrs after blowing out and before placing in crate/ tub.

Line meatal crate/ tub with cardboard. Use cardboard between each row of parts so there is no machined surface on machined surface contact able to happen.

At the end of each shift AND when finishing a layer, lightly mist the layer with general purpose rust preventative oil.

At the start and end of each shift, make sure that you thread the thread gage the ENTIRE way through the part (as shown in picture). A tool (second picture) passes through the part to create a surface for welding. So, by threading the gage the entire way through the part, you ensure that part will function as desired.

Once an hour, thread gage in past the .590” hole (from the 3/4” NPT end). This will ensure that you are breaking the bur on 3/4” NPT end as well as ensuring to remove any bur from where the .590” Hole breaks into thread.